Cryocooler Platforms

- Temperature range spanning -150°C to -273°C for staged cooling.

- Modular Stirling and pulse-tube options sized to the heat budget.

- Isolated vibration mounts protect precision bearings.

Ioncore’s cryogenic architecture combines active cryocoolers, layered insulation, and precision control to unlock ultra-low operating temperatures without compromising system integrity. Sustain electromagnet efficiency, minimize thermal drift, and extend component life with an engineered cold chain built for continuous duty.

Target temperature threshold with staged helium cooling.

Thermal drift held via adaptive shielding and feedback loops.

Uptime achieved with redundant coolant delivery paths.

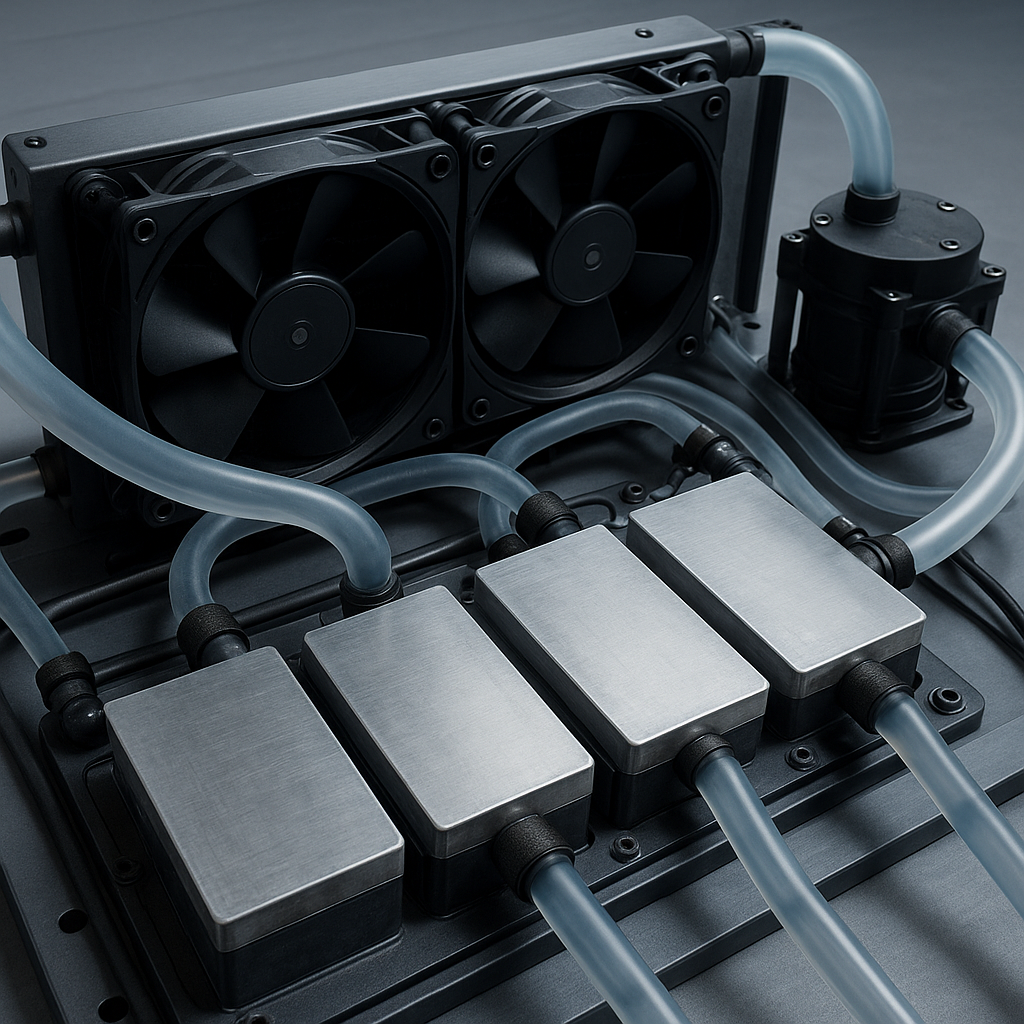

Integrated cryogenic cold chain with cooling loops and shielding.

Every component works in concert to remove heat rapidly, protect structural materials, and maintain vacuum purity. The result is a controllable environment ready for high-flux electromagnets and kinetic storage elements.

Continuous extraction per rack with surge handling for pulse events.

Ultra-high purity copper interfaces sustain rapid heat removal.

Active pumping keeps insulation voids free from moisture intrusion.

Adaptive PID loops stabilize coolant valves against load spikes.

Fit cryocoolers, heat exchangers, and vacuum envelopes according to magnetic inertia schematics. Verify alignment and thermal contact surfaces.

Charge reservoirs with LN₂ and perform staged cooldown. Transition to LHe circulation once temperatures reach sub-70K.

Activate sensor suite to watch for thermal expansion, vacuum pressure, and vibration anomalies. Feedback loops correct deviations in real time.

Automated alerts schedule coolant refills, insulation inspections, and seal replacements before performance degrades.

Cryo-rated alloys and composites mitigate stress from thermal contraction and ensure long-term reliability.

Ventilation controls and oxygen depletion sensors protect operators when handling cryogens.

Parallel coolant loops and auxiliary chillers deliver uninterrupted flow for mission-critical loads.

Secure telemetry dashboards provide global access to trends, alarms, and maintenance insights.